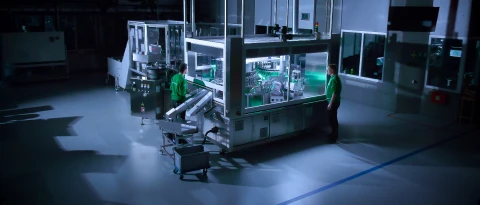

Syringe assembly machine

At AAE, we recognize the essential role that high-tech syringe assembly machines play in

the medical industry. Our state-of-the-art machines are meticulously engineered and tested

to overcome industry challenges, ensuring minimal downtime, maximized output with high-

speed operation, and reduced operational costs through efficient design and low

maintenance requirements. Contact us today to discover how AAE can elevate your syringe

assembly automation to the next level.

What is a syringe assembly machine?

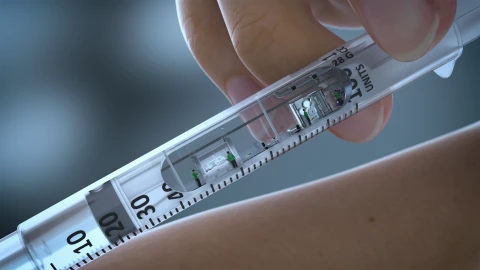

A disposable syringe is a medical device consisting of a cylindrical barrel and a thin sliding

plunger. The plunger, often equipped with a cap for an additional seal, fits tightly within the

barrel, allowing for the controlled drawing in and expelling of fluids or gasses through an

orifice at the barrel’s open end. Typically made from plastic or glass, the barrel is transparent

and marked with graduated measurements to indicate the fluid volume. Disposable syringes

are commonly used for a wide range of medical applications, thanks to their simplicity and

reliability.

Benefits of syringe assembly machines

Reliability: Crafted from the highest quality materials and subjected to stringent

testing, our machines are designed to minimize downtime and ensure consistent,

reliable production.High-speed operation: Boost your output and meet market demands with our

advanced automatic syringe assembly machines that are optimized for rapid, high-volume production.Operator Efficiency (lower operating costs): Our machines are engineered to

require minimal handling and maintenance, resulting in more efficient and cost-

effective operations.

Features and applications

Our syringe assembly machines are designed to comply with GAMP and ISO 207001

standards, ensuring data integrity, process validation, and consistent product quality. With

clear and detailed audit trails, our systems provide a comprehensive record of every

assembly step, facilitating regulatory compliance and stringent quality control.

Process steps of the syringe assembly machines

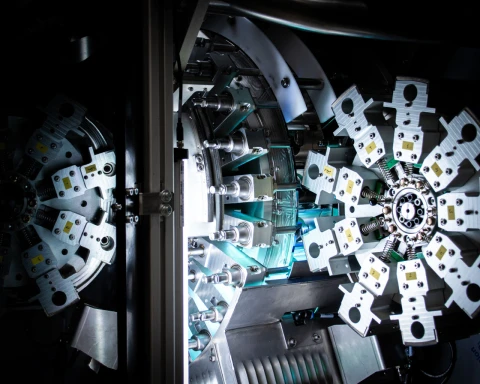

Our engineering team utilizes cutting-edge technologies to handle the precise assembly of

critical syringe components. With deep expertise in material compatibility, we design

systems that minimize the risk of damage or contamination during the assembly process. At

AAE, we understand the importance of maintaining cleanroom environments, and our

machines are equipped with advanced filtration and controlled airflow systems to ensure

contaminant-free production of assembled syringe system

Applications and industries

AAE’s syringe assembly machines are designed to meet the needs of a wide range of industries, including the medical, pharmaceutical, and research sectors. These machines significantly enhance efficiency and reduce costs by automating post-molding assembly processes, ensuring both precision and consistency in production.

- Medical industry: AAE’s machines are perfectly suited for use in hospitals and clinics, where they ensure the reliable production of syringes used in various medical treatments and procedures. Our machines maintain strict quality control, making them ideal for environments where accuracy and patient safety are paramount.

- Pharmaceutical industry: These machines also play a crucial role in the pharmaceutical industry, particularly in the production of vaccine syringes. By automating the assembly process, manufacturers can meet high-volume demands while ensuring compliance with regulatory standards.

- Research institutions: In laboratories, our syringe assembly machines streamline the production of precision syringes required for experimental and clinical research. With their ability to handle delicate components, they ensure that researchers can rely on consistent and high-quality results.

Whether your operations involve delicate medical components or require strict regulatory compliance, our plastic syringe assembly machines deliver the accuracy and performance you need. Seamless integration with existing molding lines ensures smooth workflow, while advanced features such as traceability and data integrity enhance production control and adherence to industry standards.

Explore our

Customer Cases

FAQ

AAE’s syringe manufacturing equipment is built to handle a wide variety of syringe types, making them ideal for diverse manufacturing needs. From standard disposable syringes used in medical facilities to complex, multi-part assemblies like safety syringes and multi-dose syringes, our machines are equipped to manage a broad spectrum of designs. With solutions tailored to different production volumes, AAE makes automation accessible to companies of all sizes, whether you’re a small-scale producer or a large pharmaceutical manufacturer. Our machines can also accommodate syringes of various sizes, materials, and components, offering a flexible solution for medical device manufacturers and pharmaceutical companies alike.

Yes, AAE’s automatic syringe assembly machines are highly customizable to fit your unique production requirements. We recognize that each manufacturing operation has distinct needs, from component handling to production speed and regulatory demands. Whether you require modifications for specialized syringe designs or want to optimize your line for increased efficiency, our engineers collaborate with you to tailor the system to your exact specifications. This ensures seamless integration with your existing processes and guarantees optimal performance. Learn more about how our customized syringe assembly solutions can elevate your production.

Absolutely. Our automatic syringe and needle assembly machines are designed with scalability and flexibility in mind. As your business grows or new products are introduced, our machines can be expanded or modified to accommodate additional syringe types or increased production volumes. Whether you’re scaling up to meet higher demand or adapting to new syringe designs, our modular systems can be enhanced without significant downtime. This future-proof approach ensures that your investment in automation continues to serve your evolving needs.

AAE provides comprehensive support for the integration of new equipment into your existing production lines. Our team ensures that every new machine is seamlessly integrated with minimal disruption to your operations. We focus on maintaining cleanroom environments by incorporating advanced filtration and controlled airflow systems, ensuring that your production process remains compliant with industry hygiene standards. In addition to installation, we offer detailed operator training, system calibration, and ongoing technical support to ensure your new equipment runs smoothly from the start.

AAE’s syringe assembly machines are known for their exceptional durability and long lifespan. With many of our systems in continuous operation for decades, our machines are engineered to last. Built from top-quality materials and featuring robust engineering, our equipment can perform reliably for many years with routine maintenance and occasional upgrades. This ensures a strong return on investment and consistent production output over the long term.

AAE ensures the highest levels of quality and reliability in every syringe produced by our automatic needle assembly machines. Our automatic syringe assembly systems are equipped with advanced features like vision inspection systems and real-time quality control mechanisms, which continuously monitor and verify every step of the assembly process. This minimizes the risk of defects and guarantees that every syringe meets stringent industry standards for safety and functionality. Each machine undergoes extensive testing to ensure it is fully compliant with regulatory requirements before installation.

AAE offers a complete range of maintenance services to ensure your syringe assembly automation continues to perform at peak efficiency. We provide in-depth training programs for your personnel, enabling them to handle routine maintenance tasks such as replenishing consumables and performing regular system checks. Additionally, we recommend annual check-ups by our certified technicians, who will conduct system diagnostics and make any necessary adjustments to keep your machines operating smoothly. With our proactive approach to maintenance, you can minimize downtime and extend the lifespan of your equipment.