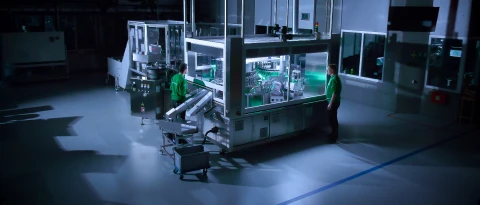

Pen injector assembly line

At AAE, we specialize in delivering advanced automation solutions for pen injector assembly lines, designed to meet the high demands of the medical and pharmaceutical industries. Our systems ensure the precise and efficient assembly of pen injectors used for delivering critical medications such as insulin, hormones, and biologics. With a focus on accuracy and reliability, AAE’s assembly lines not only meet stringent regulatory standards but also optimize production efficiency, scalability, and cost-effectiveness.

What is a pen injector assembly line?

A pen injector assembly line is an automated system engineered to assemble medical pen injectors that allow patients to administer medications with ease, accuracy, and safety. These systems are critical for producing devices used in diabetes care, hormone therapies, and other medical treatments requiring self-injection. AAE’s lines are designed for high precision, ensuring each injector is assembled to meet exacting medical standards.

Benefits of an efficient assembly line

An efficient pen injector assembly line brings numerous advantages to manufacturers. Automation significantly enhances production speed, enabling the rapid assembly of high-quality injectors with minimal errors. By reducing defects and ensuring consistency, these lines drive higher product reliability while cutting labor costs and material waste. Furthermore, AAE’s scalable systems are built to grow alongside your production needs, ensuring adaptability to future demands.

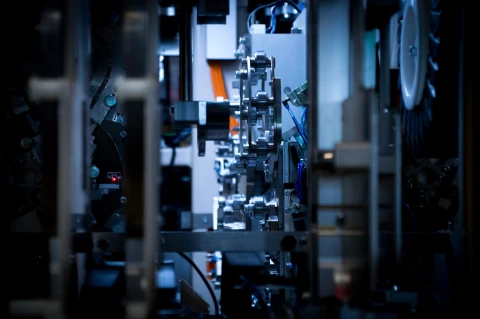

Key components of a pen injector assembly line

The pen injector assembly line is composed of several critical components that work together to ensure flawless production:

- Component feeders: Deliver individual parts like needles, barrels, and casings to the assembly stations.

- Automated assembly stations: Precisely fit and assemble each component, ensuring tight tolerances and high product integrity.

- Vision inspection systems: Check for correct alignment and assembly, ensuring each product meets quality standards.

- Testing stations: Validate the functionality and dosage accuracy of every pen injector produced.

- Packaging systems: Automatically prepare finished products for labeling, packaging, and shipment.

Steps in the pen injector assembly process

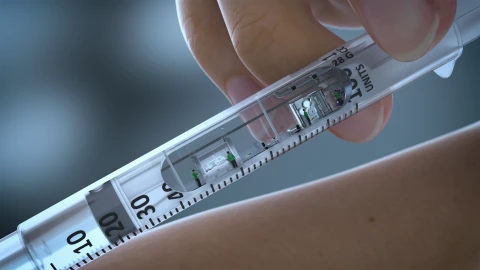

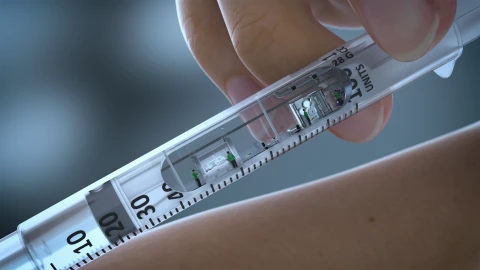

The assembly process follows a clear, structured workflow to ensure precision and efficiency. First, components like injector bodies, needles, and cartridges are fed into the system. Then, the automated stations perform precise assembly, combining these parts into a fully functional pen injector. After assembly, the product undergoes inspection and testing to verify accuracy and safety. Once approved, the injectors are labeled, packaged, and prepared for distribution.

Applications and medical industries

Pen injectors play an essential role in modern healthcare. They are most commonly used for insulin delivery, allowing patients to manage diabetes with ease. Pen injectors are also utilized in hormone replacement therapies, such as growth hormone treatments, and for the administration of biologic drugs in chronic conditions. Emergency-use injectors, such as epinephrine pens, are another critical application, ensuring timely treatment in life-threatening situations.

Explore our

Customer Cases

FAQ

Absolutely. AAE specializes in developing tailored assembly solutions that are designed to align with your unique product designs, production goals, and operational requirements. We offer extensive customization options, whether you need to accommodate complex component handling, integrate specialized features, or scale production for high or low-volume outputs. Our engineering team works closely with you to configure systems that ensure seamless compatibility with your existing processes while optimizing efficiency, precision, and regulatory compliance.

At AAE, we guarantee the quality and reliability of our machines through the integration of advanced automation technologies, such as vision inspection systems and real-time monitoring, ensuring each part is assembled to exact specifications. Our machines undergo rigorous testing protocols to meet and exceed industry standards, ensuring consistent, high-performance output. By prioritizing precision and leveraging cutting-edge quality control technologies, we deliver assembly lines that maintain product integrity and compliance across every stage of production.

AAE is committed to offering comprehensive, long-term support services after installation. We provide thorough operator training, ensuring your team is well-equipped to handle daily operations and basic maintenance. Additionally, we offer ongoing support, including regular system check-ups, troubleshooting, and technical assistance, to ensure your assembly line continues to operate at peak efficiency. We also provide system upgrades and modifications to keep your equipment aligned with technological advancements and evolving production needs.

Yes, AAE offers a wide range of additional services to enhance your pen injector assembly line. From system integration to ensure seamless operation with existing equipment, to equipment upgrades that enhance performance and efficiency, we provide solutions to optimize every aspect of your assembly process. Our consulting services also help manufacturers stay ahead of regulatory compliance and industry best practices. Whether you need a small adjustment or a complete system overhaul, AAE has the expertise to support your long-term success.

The development and implementation timeline for a custom assembly machine varies depending on the complexity and specific requirements of your project. Typically, the process spans several months, during which AAE works closely with you to ensure every detail is meticulously designed and tested. Our focus is on delivering high-quality, customized solutions within an agreed-upon timeframe, without compromising on performance or reliability.

Yes, AAE can modify or upgrade your current assembly line to enhance performance, integrate new technologies, or scale production to meet growing demands. Our expert team can reconfigure your system to improve efficiency, accuracy, and output, all while ensuring minimal disruption to ongoing operations. Whether you’re looking to add new modules, increase automation, or upgrade outdated components, AAE provides flexible, cost-effective solutions to keep your production at the cutting edge.