Printing and Assembly

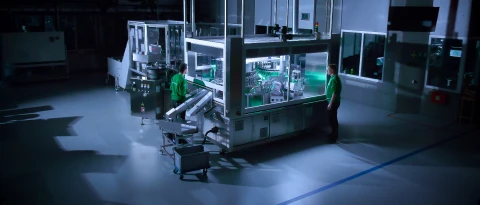

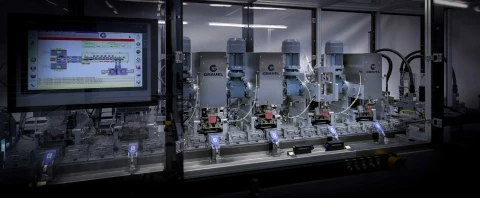

Automation

We make it happen

If you are looking for a one-stop-shop high-tech printing and assembly solution provider with a can-do approach, we can answer that call. We have specialists who understand every aspect of any assembly or printing method your product may require. Our unique combination of printing and assembly has already won favour with many industrial giants. For inkjet, dry offset and pad printing we can develop inks if you have specific requirements for your products and their deployment environments, including any pre- or post-treatments.

Integration is key at AAE. We design machines that weave the various aspects of the different processes together, where other builders just find workarounds for process conflicts. Processes that our experts create in-house. So, no fix or troubleshooting is necessary for transitions for modules supplied by other manufacturers. It is our goal to build reliable, efficient machines, without limiting ourselves to a specific automation platform. We understand reliability and sustainability also mean the availability of servicing and consumables for the machine’s lifetime (inks, plates, rollers, spares, up-to-date safety data sheets, etc.). And we know how well this drives down the total cost of ownership.

No excuses. Just perfect solutions. From a completely independent and privately owned company. Guaranteeing you get dependability, high yields and long-term profitability from your machines. You know what you want done. We know how to get it done, and in ways that maximise your profitability and reputation.

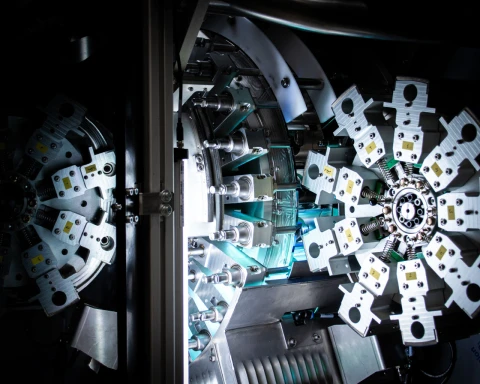

Our Automation Platforms

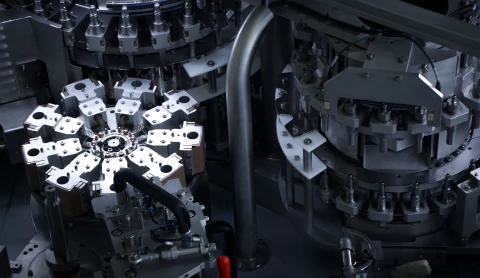

At AAE, we have a range of automation platforms for you to choose from. As we are not constrained by a single system, we can let your product and manufacturing needs lead. Together we can select the best possible fit to create an automation platform based on FMS, IMS or CMS.

- FMS is the flexible platform and the ideal solution for lower speeds with asynchronous cycle times.

- IMS is an indexed platform (linear or round) and is better suited for synchronous cycle times (up to 90 indexes per minute).

- Where you need continuous motion for high-volume manufacturing, CMS can handle up to 600 components per minute.

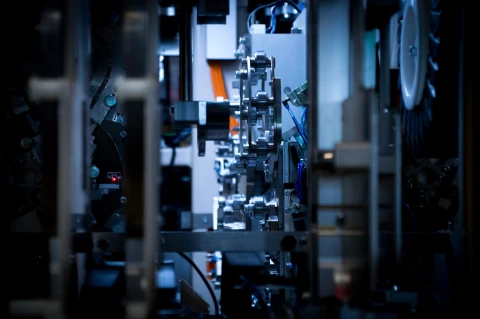

What makes us a unique supplier, is not just that we push the boundaries of technology (that’s a given) but in the way in which we can integrate printing, assembly and quality control testing technology in a single automated machine.

Creating the perfect platform is one thing, but doing this in a cost-effective way is quite another. At AAE, we never lose sight of the total cost of ownership. Downtime for repairs and frequent maintenance can cause expensive disruptions, as does having to replace a system because spare parts are no longer available. With our very own brand we carry a legacy, where reputation means everything, and our customer support is unsurpassed. Our support of your systems only stops when you are ready for an upgrade and not before it.

No excuses.

Just perfect solutions.

Inkjet Printing

We can supply fully automated industrial inkjet solutions for printing on round and shaped products in full (CMYK) colours. We already serve the automotive, medical, life sciences and consumer goods markets. Meeting the highest industrial requirements, delivering the highest quality.

Perhaps you already know which form of inkjet printing you require, but if you have not yet completely decided or are interested in learning more about what inkjet printing has to offer today, we would be happy to share this with you. We always create unique and product-dedicated inkjet printing solutions for our customers. Whatever your inkjet printing needs, we can develop a tailormade system to empower your organisation.

Dry Offset Printing

We do not have a preferred printing process, we employ the most appropriate method for your needs. So, if it is dry offset printing you desire, and you are looking for a partner who can design and develop high-speed and multiple colour systems, look no further. We can integrate dry offset printing with component assembly in a single machine, optimising the process on the smallest possible footprint. We have supplied countless product and client-specific dry offset printing systems for a multitude of different products.

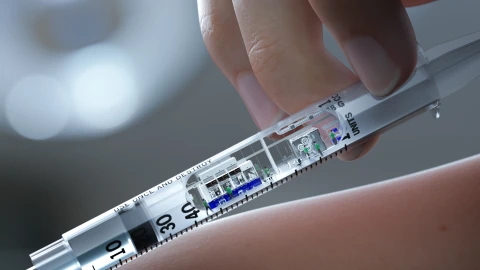

Pad Printing

Pad printing is an ideal option for automotive, medical, life sciences or consumer goods. When working in automotive, medical, life sciences or consumer goods markets, a good option could be pad printing. We can provide you with fully automated, high-quality, multiple colour pad print systems for printing drug-dispensing devices and other objects. Nothing is too complex for our pad printing systems. They can handle intricate custom product shapes printed in up to twelve different colours in a single machine. So, if you need a fully automated, multiple colour pad printing and assembly machine, you can depend on AAE to supply a best-in-class system with an optimised footprint.

Ultrasonic Welding

In designing a system unique to your needs, we collaborate with all the leading ultrasonic welding equipment manufacturers. You can depend on us to design a consistent ultrasonic welding process, even when batch sizes are as low as one. With smaller batches, we employ flexible and programmable ultrasonic welding settings (parameters) to minimise fluctuations in the manufacturing process. Ultrasonic welding and assembly in one, that’s what you get from AAE.

Leak testing

If leak testing is imperative for your manufacturing process, we can integrate leak-testing equipment from various suppliers to answer your specific needs. Just imagine having assembly systems with fully automated leak testing on board. Our systems are tailored to support the accurate and high-quality leak testing and automated handling of your products.

In designing a system unique to your needs, we collaborate with all the leading leak-testing equipment manufacturers. If you need consistent high-speed leak testing, you can call on our extensive experience in correct clamping and sealing to support high sensitivity. You can even opt for the integration of several sequential leak testing stations in a single system.

Pushing Technical Boundaries

We push the boundaries of what is technically possible to empower you. With every high-end solution integrating seamlessly with your needs and requirements. To boost your competitive edge in your industry, so that you can lead the market through smarter, faster, more stable and cost-effective manufacturing.

Explore our

Customer Cases

Our Business Lines

Ultra Conditioned Precision Modules

Advanced OEM Systems