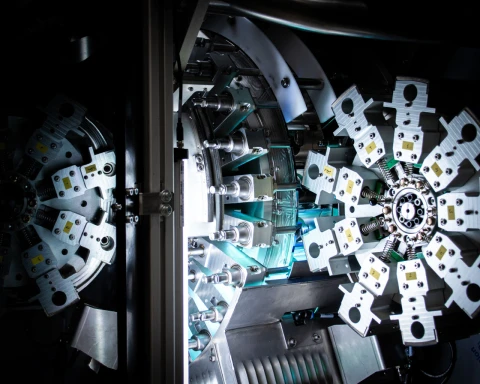

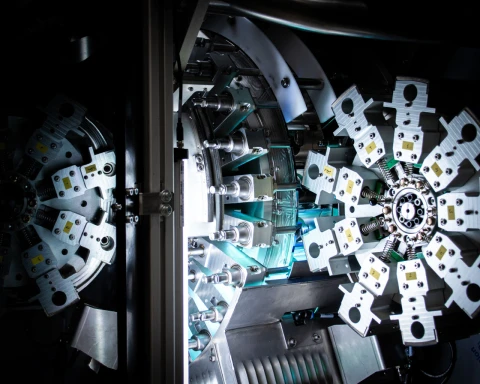

Autoinjector assembly machine

At AAE, we recognize the critical role that high-tech autoinjector assembly machines play in modern healthcare and medical device manufacturing. Our machines are designed with both performance and reliability at the forefront, addressing the most pressing industry challenges. By integrating cutting-edge technology with a focus on long-term efficiency, our machines minimize production downtime, significantly boost output with fast cycle times, and reduce overall operating costs. With optimized designs that require minimal handling and maintenance, AAE’s solutions can revolutionize your autoinjector assembly processes, ensuring your production stays ahead of demand and regulatory compliance.

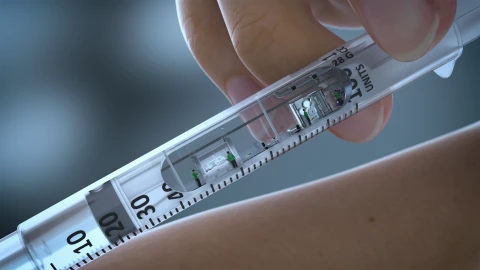

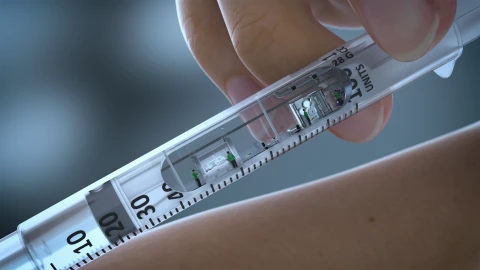

What is an autoinjector?

An autoinjector is a medical device designed to administer a pre-measured dose of medication with ease and precision. It simplifies the injection process, enabling patients to self-administer medication with minimal medical supervision. Autoinjectors are commonly spring-loaded devices that, when pressed against the skin, trigger the injection of medication automatically, ensuring consistent and accurate delivery—vital for treatments like insulin, epinephrine, and other biologics.

Key benefits of autoinjector assembly machines

AAE's autoinjector assembly machines offer a range of critical benefits, making them indispensable in high-volume, precision-driven production environments:

- Reliability and durability: Constructed from top-tier materials and rigorously tested under demanding conditions, our machines are built to last. Their robust performance ensures minimal downtime, allowing for uninterrupted production.

- Enhanced speed and output: With high-speed operation, our machines significantly increase production capacity, helping manufacturers meet stringent market demands without compromising on quality.

- Operational efficiency: Engineered for low handling and maintenance, our machines empower operators to focus on productivity rather than troubleshooting. Reduced manual intervention leads to lower labor costs and higher operational efficiency.

- Cost reduction: By integrating automation into the assembly process, you can cut down on human error, material waste, and excessive labor costs, ultimately delivering a leaner, more cost-effective production line.

Features and applications

Our autoinjector assembly machines are not only fast but also meticulously designed to meet stringent industry standards like GAMP and ISO 207001. These features make them ideal for a wide range of applications, from high-precision medical devices to mass-market injectors:

- Data integrity & traceability: Built-in compliance with regulatory standards ensures that every product produced has a comprehensive audit trail. This is essential for quality control, process validation, and meeting global regulatory requirements.

- Customizable automation: Our machines can be tailored to accommodate specific production needs, offering flexibility for manufacturers of various injector designs and sizes. Whether you're producing autoinjectors for biologics, insulin, or emergency medications, our systems are up to the task..

The autoinjector assembly process

Precision is at the heart of our autoinjector assembly process. AAE’s engineers bring unmatched expertise in handling miniaturized components and sensitive materials. Key aspects of our assembly process include:

- Advanced component handling: We design systems that manage even the smallest components with extreme accuracy, reducing the likelihood of damage or misalignment during assembly.

- Material compatibility: Our machines are built with deep knowledge of materials used in autoinjector components, ensuring smooth assembly without causing material degradation or contamination.

- Cleanroom Integration: Understanding the critical need for sterile environments, our machines come equipped with advanced filtration and controlled airflow systems, ensuring the production process complies with cleanroom standards and reduces the risk of contamination.

Applications and industries

- Medical Device Manufacturers: Companies specializing in medical devices will find our solutions indispensable for ensuring precision, compliance, and efficiency in their production lines.

- Plastic Molding Companies: With seamless integration into existing molding lines, our machines enhance post-molding assembly, cutting down on labor costs and reducing human error.

- High-Volume Production Facilities: Whether you're producing millions of units annually or scaling up, our machines are built to handle high-capacity manufacturing with ease, while maintaining quality and traceability.

Explore our

Customer Cases

FAQ

AAE’s autoinjector assembly systems are engineered to handle a wide range of autoinjector devices, from single-dose autoinjectors to more advanced, multi-dose solutions. Our customizable machines can accommodate products designed for chronic treatments like insulin, as well as emergency-use injectors such as epinephrine pens. Whether you’re producing high-volume, mass-market injectors or specialized devices with unique specifications, our assembly systems are designed to adapt, ensuring precision, scalability, and compliance with medical standards. Learn more about how our systems can be tailored to different autoinjector types here.

Yes, AAE specializes in creating customized autoinjector assembly solutions that align with your specific production requirements. Our machines are fully customizable to suit various manufacturing needs, whether you’re scaling up for mass production or focusing on highly specialized, smaller-batch autoinjectors. We work closely with you to configure automation systems that fit your unique product designs, ensuring seamless integration into your existing production environment. Explore our range of custom assembly machines here.

Absolutely. AAE’s assembly machines are designed with scalability in mind, allowing for easy expansion and adaptation to meet future production demands. Whether you’re looking to scale up your production volume or introduce new product lines, our systems can be reconfigured or expanded with additional modules and upgraded technologies. This future-proof design means you can adapt to market changes without needing to invest in entirely new equipment. Discover how our scalable autoinjector solutions can evolve with your business here.

AAE ensures a seamless integration of new equipment into your existing production lines, with minimal disruption. Our systems are designed to fit into cleanroom environments and come with advanced filtration and airflow technologies to maintain hygiene standards. We also provide comprehensive on-site support, including operator training, system calibration, and validation to meet regulatory requirements. With our expertise in system integration, we ensure that your new machinery works in harmony with your current processes.

AAE’s autoinjector assembly machines are built for long-term reliability. Our oldest machines have been in operation for over 30 years, showcasing the durability and craftsmanship that go into each system. With regular maintenance and occasional upgrades, our machines can continue to perform at high levels for decades, offering a strong return on investment while having a low impact on the environment.

We prioritize quality and reliability in every step of the assembly process. AAE’s machines are equipped with real-time vision inspection systems, ensuring that every component is correctly assembled and aligned. By incorporating rigorous testing and data integrity protocols, we guarantee that each autoinjector meets the highest standards of safety, functionality, and accuracy. This attention to detail helps minimize defects and ensures that you consistently deliver reliable products to the market.

AAE offers comprehensive maintenance and support services to ensure your autoinjector assembly machines continue to operate efficiently. We provide operator training, equipping your team with the skills needed for day-to-day operations, as well as guidance on routine maintenance tasks such as supplying consumables and verifying system settings. In addition to regular upkeep, we recommend an annual inspection by our certified technicians to ensure optimal performance. Our support includes troubleshooting, system updates, and part replacements when necessary.